The Inkbit Digital Factory

- jenslow1

- Jul 21

- 2 min read

Updated: Jul 24

In today’s race to innovate, traditional prototyping workflows can’t keep up. Lengthy lead times, limited material options, and costly design revisions often stand between your idea and its real-world validation.

When you prototype with Inkbit, you don’t just test a part. You validate the future of your product line.

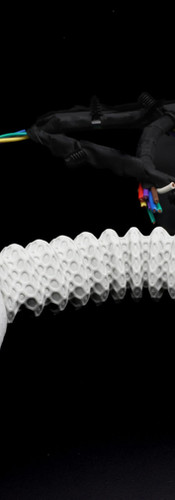

Built for What's Next

That’s why product teams across aerospace, medical, electronics, and industrial sectors are turning to Inkbit’s Digital Factory. Your next-generation production platform that radically transforms prototyping with end-use functionality and performance being top of mind. Better prototyping results start with getting in touch with our expert design to manufacture team.

From Prototype to Production-Ready

Unlike conventional 3D printing workflows, prototyping with Inkbit doesn’t hit a wall when it’s time to scale. Once a design is validated, that exact geometry and material configuration can be queued for low-volume or high-mix production using the same Digital Factory infrastructure. That means fewer delays, no retooling, and total confidence in every production run.

What Our Customers Say

“We were able to cut development time by 60% and reduce cost per iteration by nearly 80%. Inkbit changed how we approach product launches.”

— VP of R&D, Tier-1 Medical OEM

“The part we thought would be 3 separate assemblies became one. Inkbit's digital materials made it feel like we unlocked a cheat code.”

— Design Engineer, Defense Electronics Supplier

Partner with the Future of Prototyping

If you're still using outdated methods for testing designs, it's time to experience what a true digital production ecosystem feels like.

Inkbit’s digital factory empowers your team to:

Iterate faster and without compromise

Prototype end-use functionalities

Access to expert design services

Transition seamlessly to scale